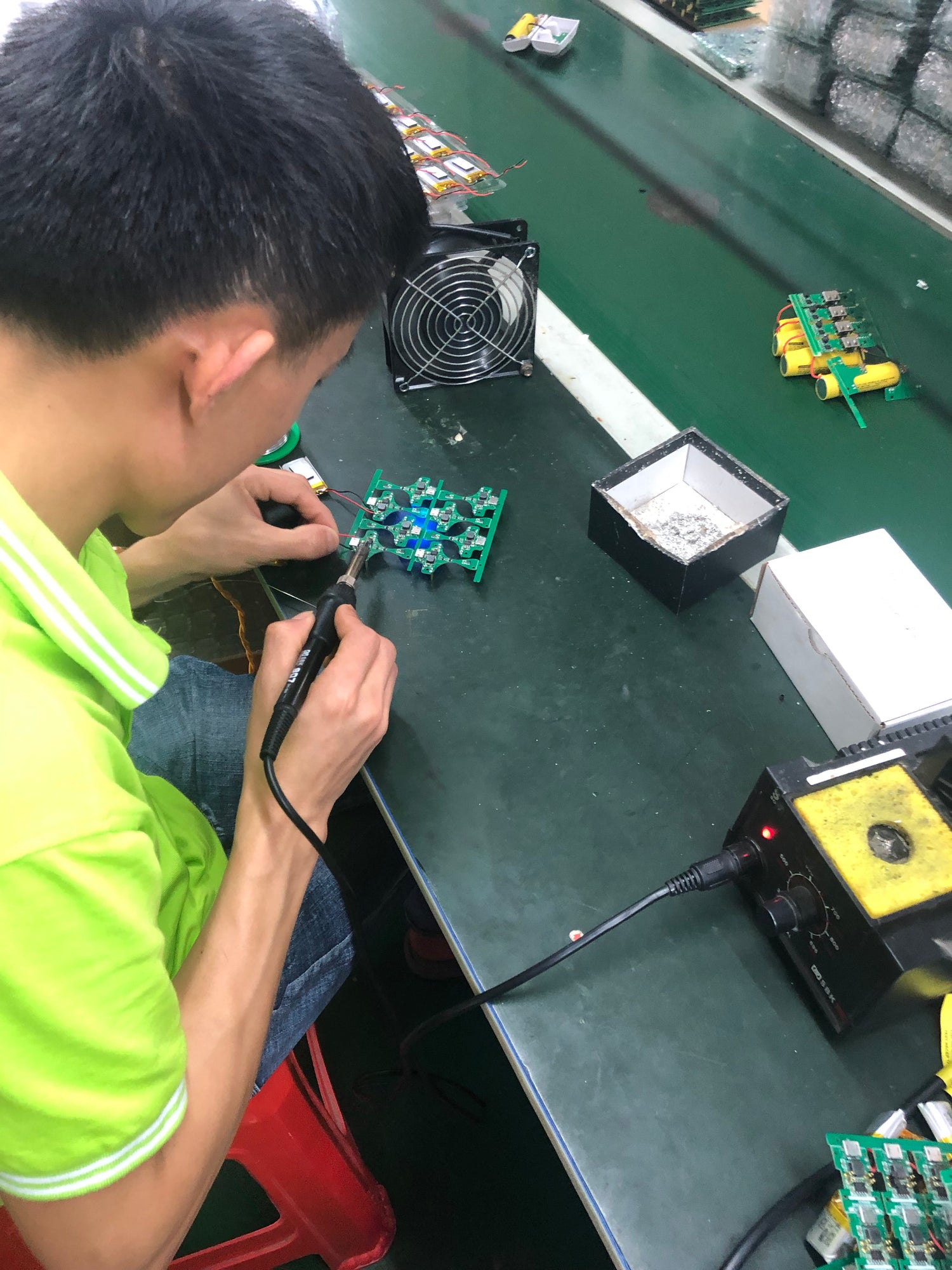

Quality Control

Quality control assures that your products arrive on time and in perfect status. It is important to understand that even before production starts, we need to make sure the factory can manufacture the requested products of certain standards.

General Inspection

For Basic plans, we will check your products based on Level Ⅱ, AQL2.5. AQL stands for Acceptance Quality Limit and is a term related to the maximum number of defects that buyers and suppliers have agreed on in a batch. AQL 2.5 means the acceptable level of major defective goods is 2.5% of the total order quantity.

If the batch produced contains a defect level that exceeds 2.5% defects, then the quality of the product is not living up to the agreement. For example, if we carry out AQL2.5 quality check No.II Standard ( No. I am loose, No. II is standard, No. III is strict), Among 501-1200 pcs full products inspection (sample size = 80 pcs), 5 pcs minor defectives are acceptable, but the defectives found out should be replaced.

Full Inspection

Pair text with an image to focus on your chosen product, collection, or blog post. Add details on availability, and style If you think General Inspection ( based on AQL 2.5) is not good enough for you, you hope to reduce the defect rate to 0%, we will provide you extra full service, which means we will follow the standards of a full inspection and check all the products 1 by 1 ( mostly based on function & appearance), the full inspection fee will be decided by the labors to be used, normally in China, the labor force is about 4-5 USD/hour.

We will adopt more quality checking steps for you if you buy our Pro Service, as raw materials check, half-assembled products check, final product checking, etc., or even provide a review.